1. The processing flow selects the pipe diameter corresponding to the self-cleaning filter according to the processing flow.

2. Physical and Chemical Properties of Filter Media The acid and alkali properties of filter media are used to select the types of materials

3. The concentration of suspended substance in the filtering medium is selected to pass through several stages of filtration according to the concentration of suspended substance in the medium.

4. The filtering accuracy required by the customer is determined according to the size of medium particles, but it is not that the higher the accuracy is, the more frequent cleaning of the filter will be caused due to high accuracy and easy blockage.

5, the system of pipeline pressure according to the pressure of the pipeline system to choose, is generally 1.0mpa and 1.6mpa, has a higher pressure index of 2.5mpa. Pretreatment of water filtration refers to the removal or reduction of suspended solids and colloid in water to a certain extent, and the process that meets the general water requirements is called water pretreatment. In addition to the above important parameters, there are also some preprocessing methods that you can refer to.

Working principle:

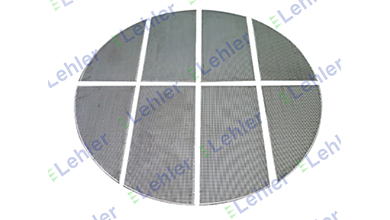

Working principle:The stock solution enters the filter through the liquid inlet. During the filtering process, impurities in the water accumulate on the stainless steel filter screen, and impurities in the inner layer gradually accumulate.

(1) Automatic cleaning: when the filtering time reaches the set value, the automatic cleaning process will be started: the electric control system gives a signal, the motor starts to work, the rotation of the motor drives the drive shaft to rotate, the scraper removes impurities accumulated on the filter screen, and the motor stops working after the cleaning time reaches the set value. The blowdown valve opens to start blowdown.

(2) Manual cleaning: the motor runs continuously to drive the drive shaft to rotate, the scraper continuously removes impurities on the filter screen, and when the time set value is reached, the drain valve opens to start draining.

(3)Differential pressure cleaning (optional): when the differential pressure between the inlet and outlet reaches the set value, the motor starts to work, the motor rotates to drive the drive shaft to rotate, the scraper removes impurities accumulated on the filter screen, and the motor stops working after the cleaning time reaches the set value.

Return

Return