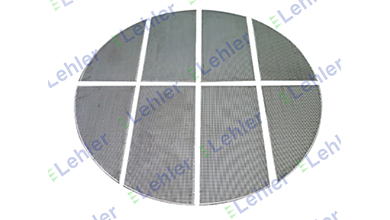

At present, most johnson screen uses trapezoidal silk. There are many advantages to using trapezoidal silk:

1. Continuous gaps greatly increase the area of water passing through, so contact with aquifer is better.

2. The V-shaped section structure avoids blockage and ensures smooth circulation.

3. Continuous pores can be effectively used for a long time.

4. Trapezoidal filter tube has firm structure, high porosity and accurate gap size.

5. Trapezoidal wire filter tube is easy to backwash, has long service life, is safe and reliable, and has low comprehensive cost. Sieve plates have good filtration and dehydration effects in solid-liquid separation and solid-solid separation. Johnson screen is mainly used in wastewater treatment, laundry water purification, poultry, fisheries, fruits and vegetables wastewater treatment industry.

Advanced welding technology and reasonable supporting structure, installed on high-frequency johnson screen, will not cause wire breakage and wire breakage due to metal fatigue deformation and desoldering, resulting in the separation of screen and flat iron. The raw materials of the stainless steel johnson screen are high-quality wear-resistant stainless steel wire (202T), the screen wire has high strength and corrosion resistance, and the trapezoidal wire structure is wear-resistant and anti-smashing. The reversible johnson screen sheet is mainly used for chamfering the screen wire in the production process of the screen sheet, and can be manually or mechanically overturned after one side is seriously worn in the use process, thus effectively prolonging the service life of the screen sheet by more than 30%.

Return

Return